cyber® simco® drive 1 – servo drive

connective – intelligent – safe

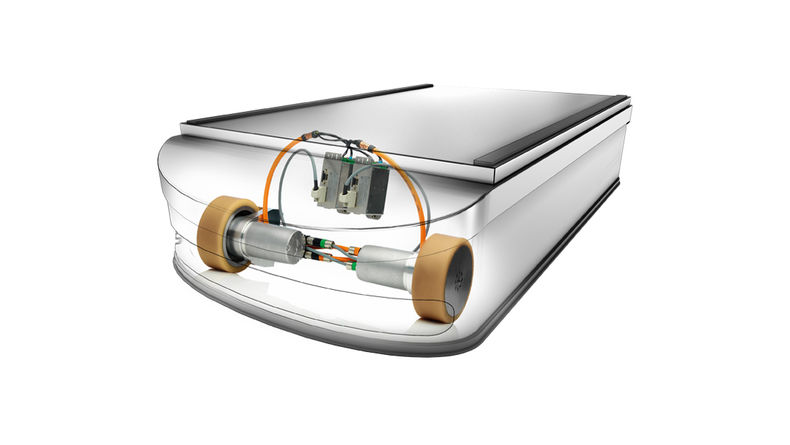

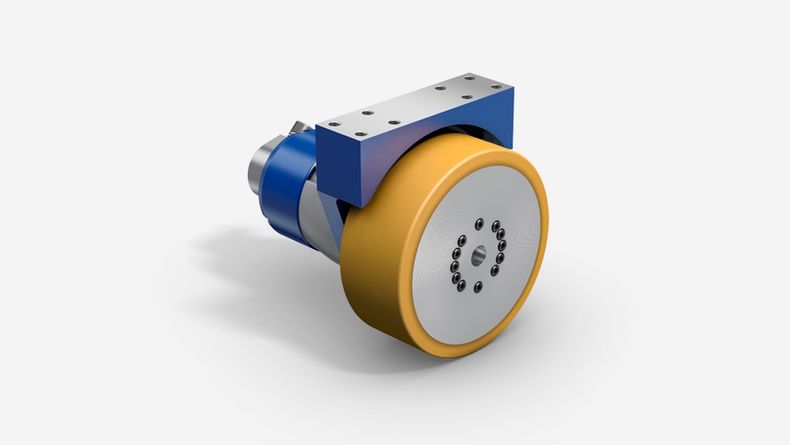

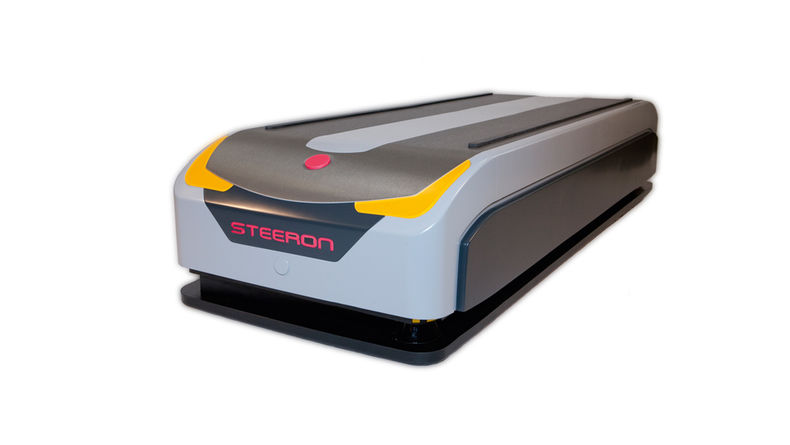

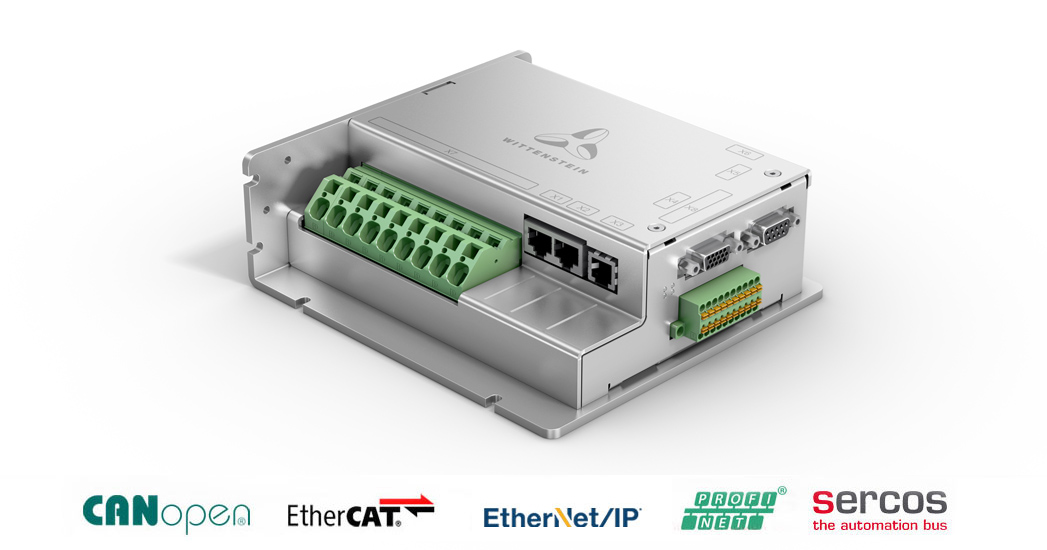

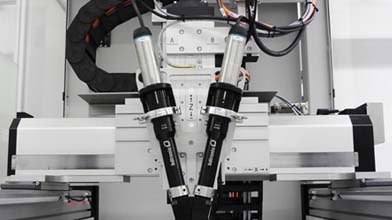

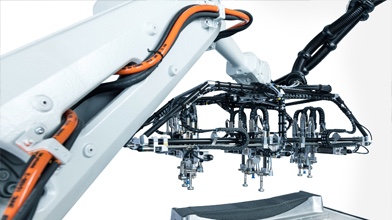

In combination with various servo motors and servo actuators, cyber® simco® drive 1 is the ideal solution for fast and precise motion and positioning tasks as well as mobile applications. With a continuous output of up to 2.5 kW and a short-term peak output of 5 kW, the servo drive with protection class IP20 is suitable for use in automated guided vehicles or in control cabinets.

![]() For a reduced project planning workload in your electrical design, the products are available in EPLAN.

For a reduced project planning workload in your electrical design, the products are available in EPLAN.

Downloads

Excellent solution for complex motion tasks

Connectivity

- Various fieldbus interfaces for connection to different controllers

- Various encoder interfaces

Intelligence

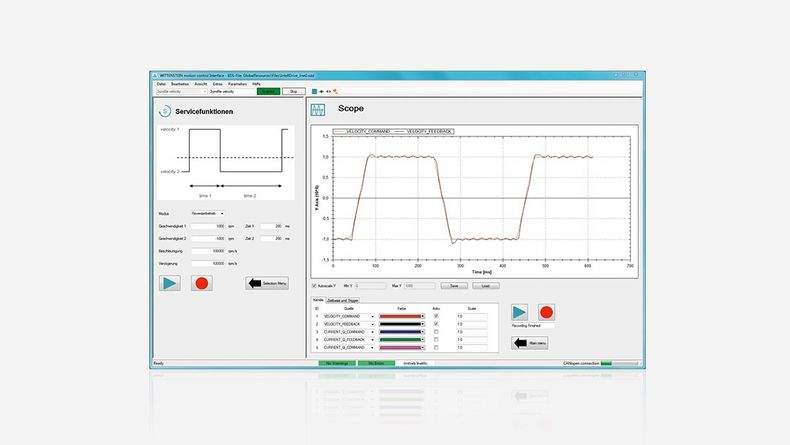

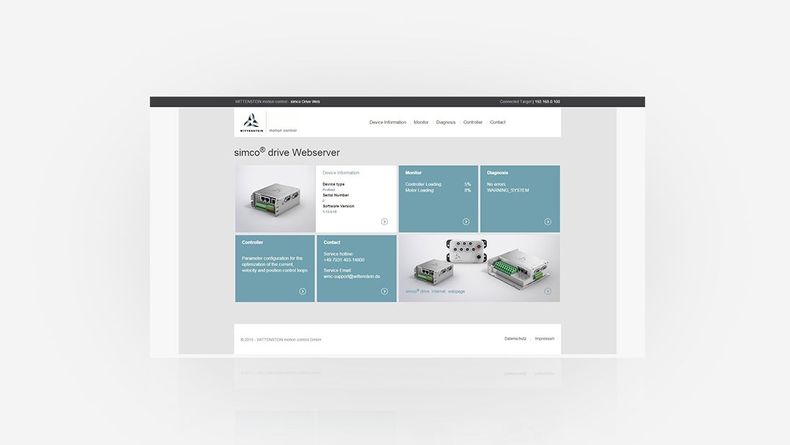

- MotionGUI software with comprehensive functions for diagnostics, optimization and parameterization

- Web server for status analysis and monitoring of the drive system

Safety

- Integrated safety function STO according to SIL3 / PL e

- Safe galvanic isolation of logic and power

- High transparency in fault diagnosis and function monitoring

Flexibility

- Compact design

- Flexible programming of motion tasks thanks to integrated PLC functionality

Easy installation & commissioning

- Electronic type plate

- Support of PLC-specific drive profiles and function blocks

Productivity

- Switching frequency from 8 to 32 kHz

- Current control resolution of 14 bits

- Ideal for high-precision torque control and dynamic processes

Product highlights

The cyber® simco® drive 1 range includes servo drives for sine-commutated servo motors in the voltage range from 12 to 60 VDC and a maximum power up to 5 kW. The servo drives are the ideal solution for automated guided vehicles or are suitable for use in control cabinets. In combination with the intuitive MotionGUI software, simple parameterization, commissioning and optimization of the system as well as flexible programming of applications is possible.

Maximum power up to 5.000 W

Support of PLC-specific drive profiles and function blocks

Safe shutdown of the system in case of emergency thanks to integrated STO (Safe Torque Off) safety function according to SIL3 without loss of productivity

Electronic name plate enables automatic and safe parametrization of the motor

Numerous fieldbus interfaces and decentral intelligence