cyber® iTAS® system

for Automated Guided Vehicles (AGV)

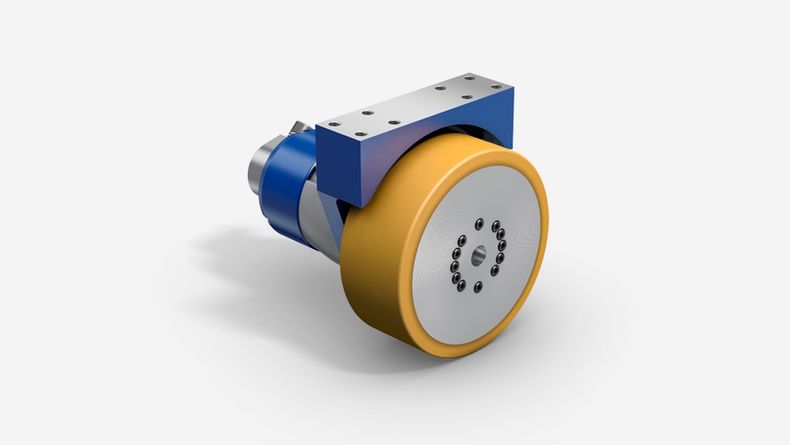

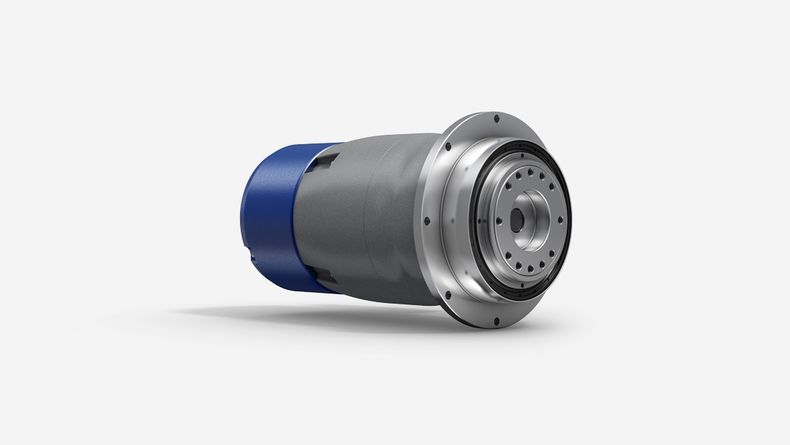

The first completely scalable, modular drive system for AGV

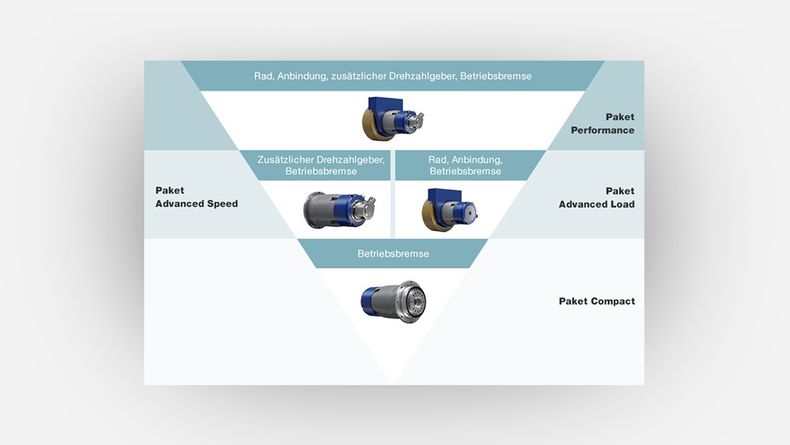

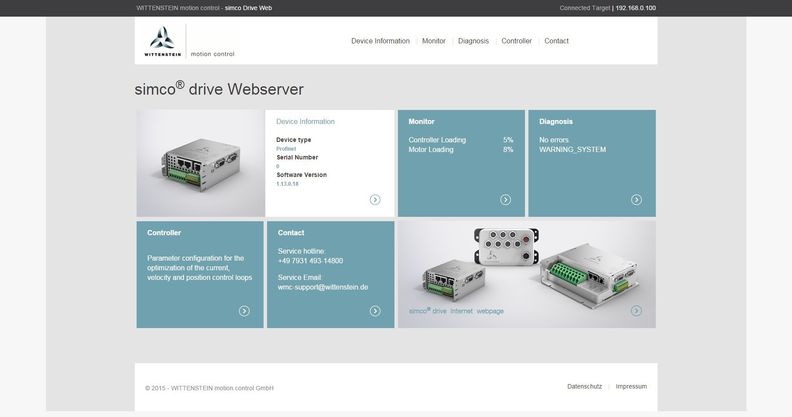

What is special about cyber® iTAS® is its simplicity. With its diversity, efficiency and individual scalability, our fully integrated, modular servo drive system offers an innovative modular solution specially for use in Automated Guided Vehicles. The combination of a freely configurable actuator system, an intelligent servo drive series and integrable, branch specific components permits maximum flexibility when realizing new vehicle concepts – safe and space-saving in the smallest installation space.

Different equipment packages mean that cyber® iTAS® can be designed to suit specific applications, thereby effectively simplifying the process of vehicle design.

Learn more about the new generation cyber® iTAS® system 2

With cyber® iTAS® systems we are a worldwide partner in the Encompass program of Rockwell Automation.

Downloads

- Catalog iTAS® (4 MB)

- Flyer small servo drive system (Generation 2) (2 MB)

- Operating manual (650 KB)

WITTENSTEIN - North America

1249 Humbracht Circle

Bartlett, IL 60103

1 630 540-5300