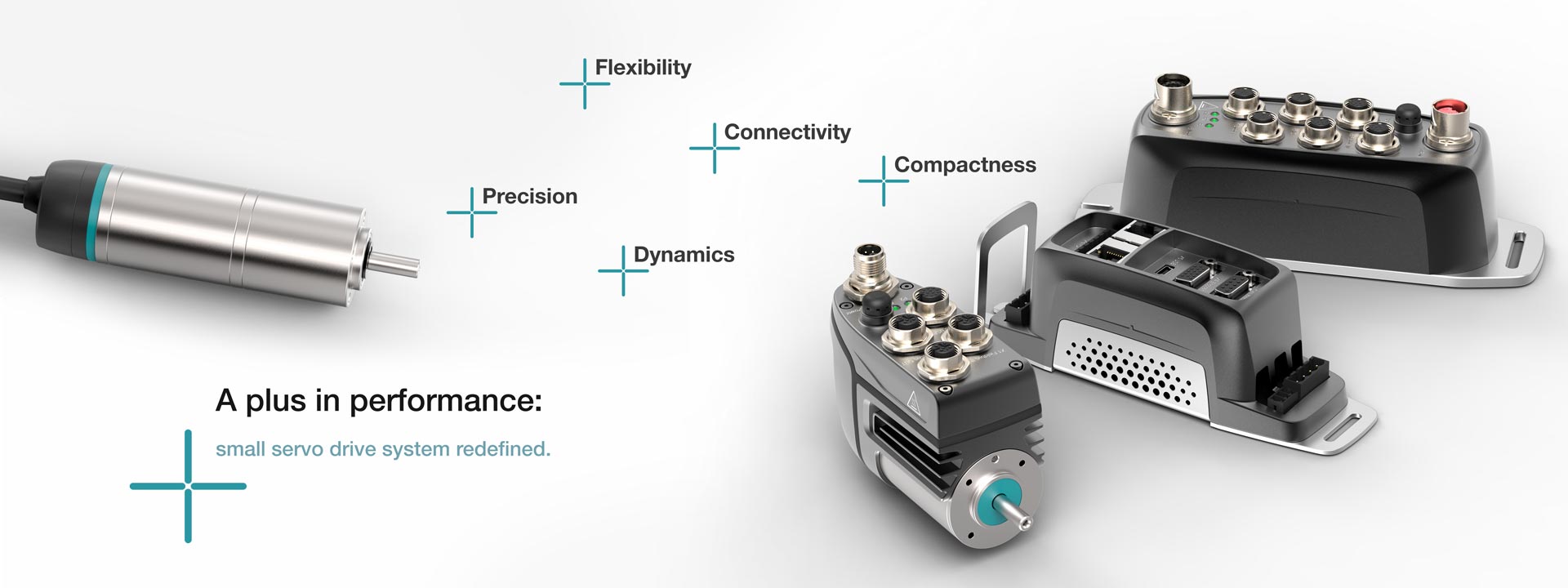

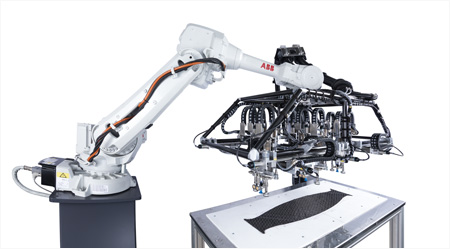

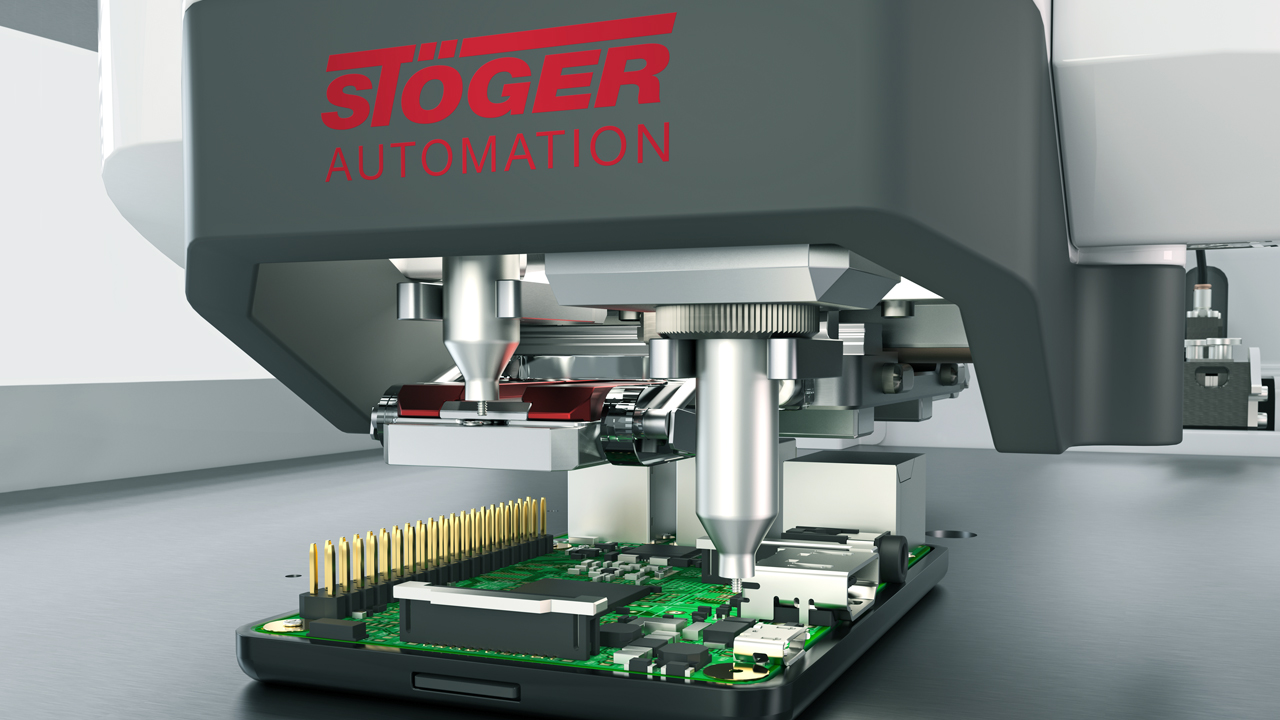

The new generation of our industrial small servo drive system sets the standard

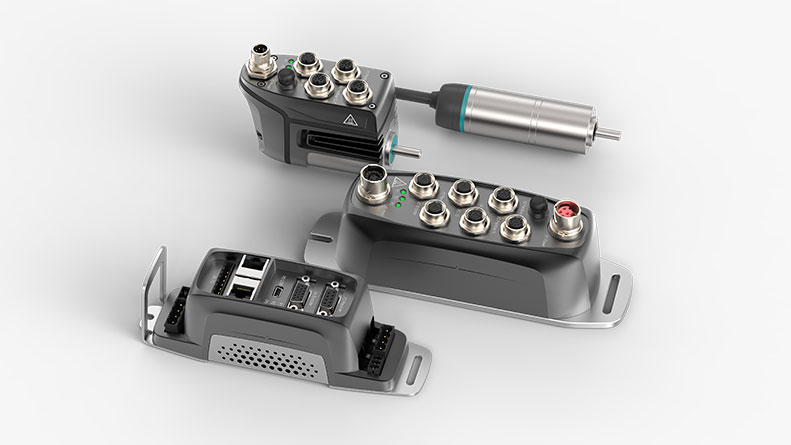

Particular highlights are the newly designed cyber® simco® drive 2 servo drives: They are up to 30% more compact than their predecessor and offer maximum connectivity with their multiple ethernet interface. They also feature real-time CIP sync functionality, decentralized intelligence and STO safety function. The new drives have also made it possible to realize the compact drive system cyber® dynamic system.

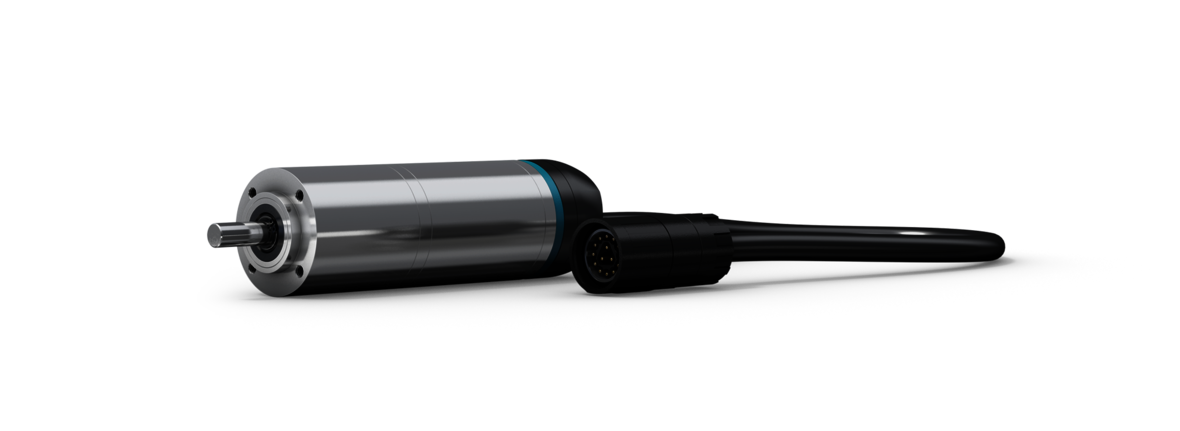

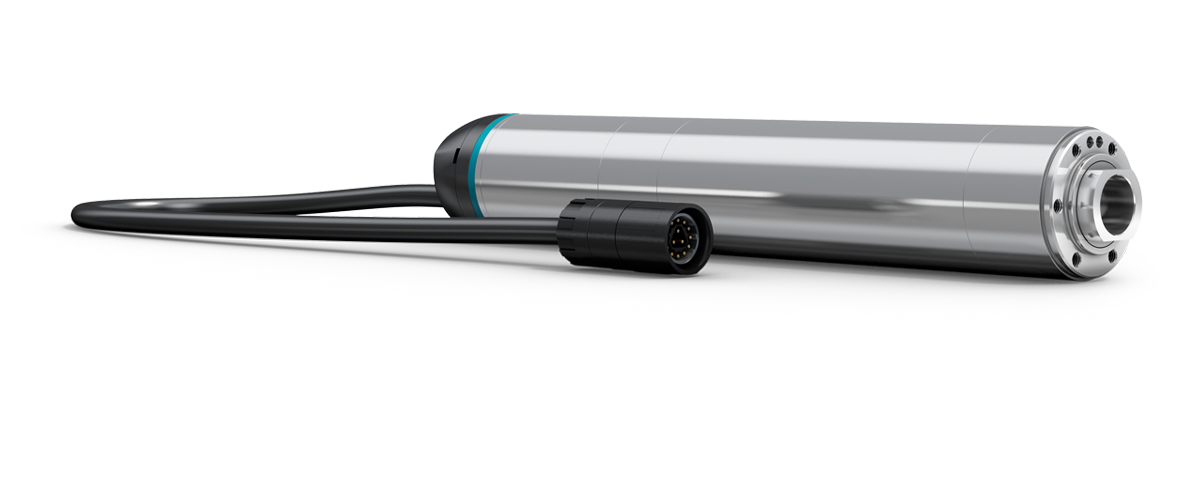

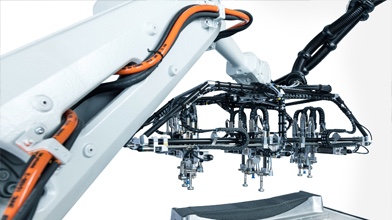

The motor-integrated version impresses with its decentralized intelligence directly on the axis and saves space in the control cabinet.

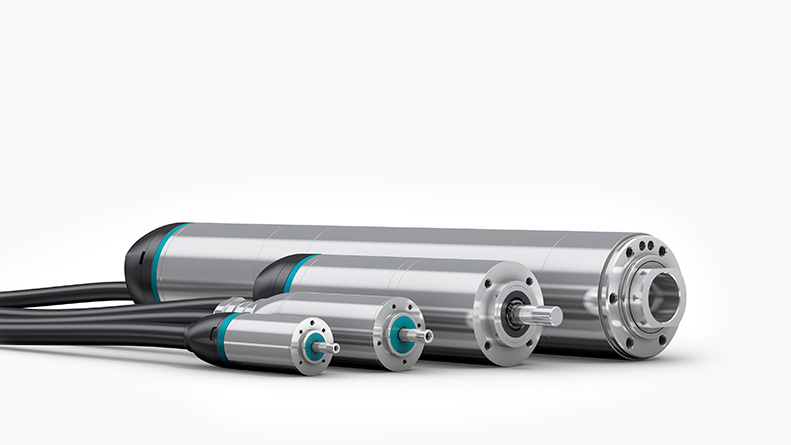

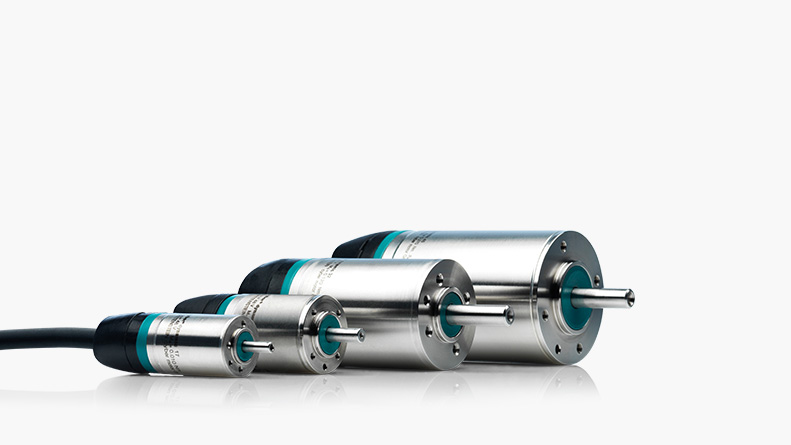

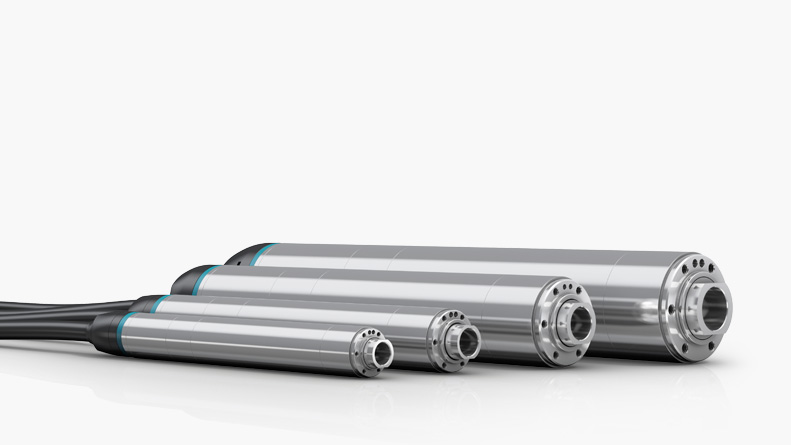

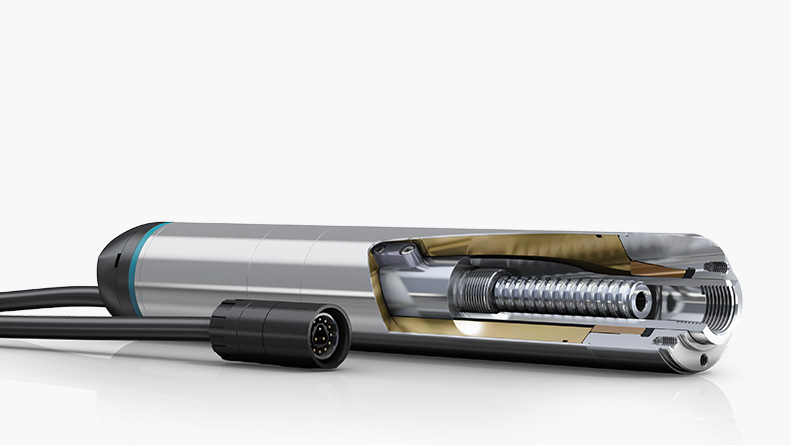

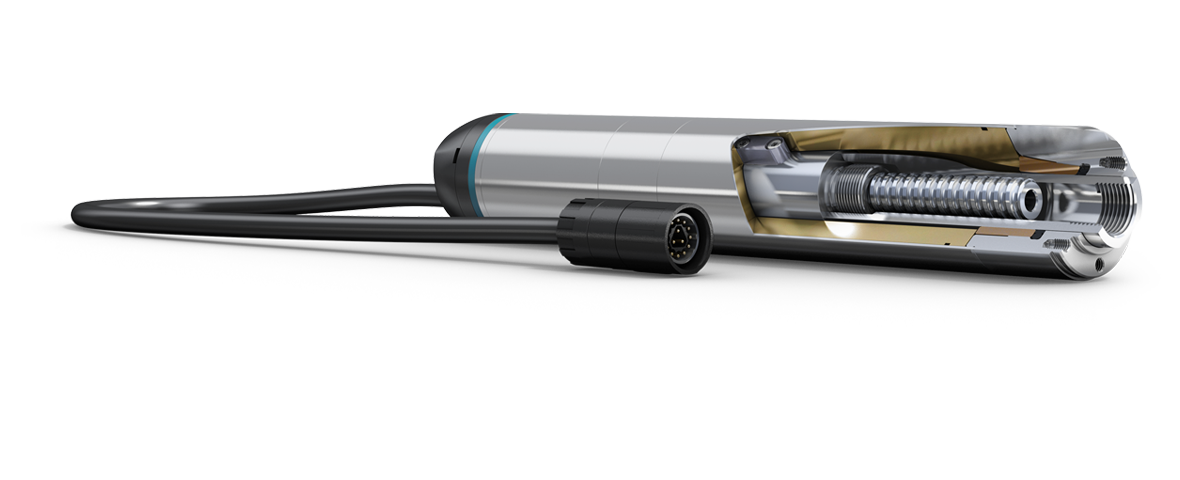

The servo motors of the cyber® dynamic line are now optionally available with a multiturn encoder (size 32/40), holding brake (size 40), planetary gearbox or ball screw drive. All this offers you never-before-seen freedom in machine design.

Whitepaper Download

Increasing machine productivity by using an Energy Harvesting multiturn encoder system

The Energy Harvesting principle is a technology that can be used to realize miniaturized, maintenance-free and energy self-sufficient multiturn encoders. Read our whitepaper to find out how the technology is applied in a multiturn encoder system, what the advantages are of using such a system and how the new technology was successfully implemented.

Recommendations for the deployment of third-party servo drives with EtherNet/IP CIP SyncTM

Machine manufacturers from different industrial segments have high standards for dynamic and precise motion control applications in real-time. By integrating CIP SyncTM in third-party servo drives, it is possible to meet these requirements. Read our whitepaper to learn more about the possibilities and advantages.

Excellent solution for complex motion tasks

Connectivity

- Multi-Ethernet version for maximum flexibility

- Many real-time capable fieldbus interfaces

- Automatic parameterization thanks to electronic name plate

Compactness

- Size of the new controllers reduced by approx. 30%

- Connection elements arranged in the front allow simple pin assignment

- The cyber® dynamic line makes extremely compact drive solutions possible

Flexibility

- Modular principle enables optimum solutions for a wide range of applications

- Optional integration of a multiturn encoder, holding brake, gearbox or ball screw drive to extend motor function

Dynamics

- Mass inertia-optimized motors for maximum acceleration

- Real-time capable and isochronous Ethernet communication

- Decentralized PLC functionality to relieve the automation system

Precision

- Absolute encoder with an encoder resolution of 12 bits

- High current resolution of 14 bits for high-precision torque control

- Controllers are designed for maximum currents of up to 30 A

Robustness and safety

- Motors available in protection classes up to IP69K

- 12 to 60 VDC wide range input

- Integrated safety function STO meets safety requirements in accordance with SIL3

Reproducibility

- High process reliability thanks to reproducible processes

- Easy integration into your fieldbus systems

Consulting and sizing

- Individual on-site consulting

- Telephone support hotline

- Sizing with cymex®

- Documentation in EPLAN

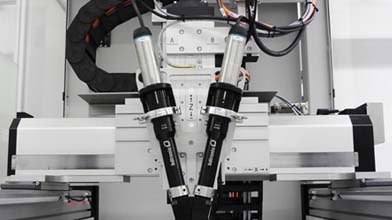

cyber® simco® line

The cyber® simco® line includes servo drives for sine-commutated servo motors in the voltage range from 12 to 60 VDC and a maximum capacity of up to 5 kW. The servo drives are availabe as control cabinet variant or in a decentralized design with protection rating IP65. In combination with the intuitive MotionGUI software, simple parameterization, commissioning and optimization of the system as well as flexible programming of applications is possible.

Simple to install using a rail clip – perfect design for cabinets

Space-saving installation thanks to stackability and user-friendly pin assignment

Extremely compact: up to 30% installation space saving

Numerous fieldbus interfaces and decentral intelligence

Simple installation in the machine without an additional enclosure thanks to protection class IP65

Safe shutdown of the system in case of emergency thanks to integrated STO (Safe Torque Off) safety function according to SIL3 without loss of productivity

Support of PLC-specific drive profiles and function blocks

Regular software releases to integrate new functionalities

Electronic name plate enables automatic and safe parametrization of the motor

High precision and dynamic torque control to achieve higher machine output

cyber® dynamic line

cyber® dynamic system

cyber® power supply

The efficient DIN rail power supplies of the cyber® power supply range perfectly complement the industrial small servo drive system. The portfolio includes single- and three-phase DIN rail power supplies, which perform with an output voltage of 24-55 VDC and with a power of up to 960 W.

Easy mounting thanks to DIN rail design

Compact design

Optimized overload behavior (short-term overload capacity up to 150%)

Efficiency up to 95%

Single- and three-phase wide-range input

Use in practice

Applications

Downloads

Contact us

Is there anything you'd like to know about the small servo drive system? Do you require personal advice?

If so, please contact us directly. We look forward to hearing from you!