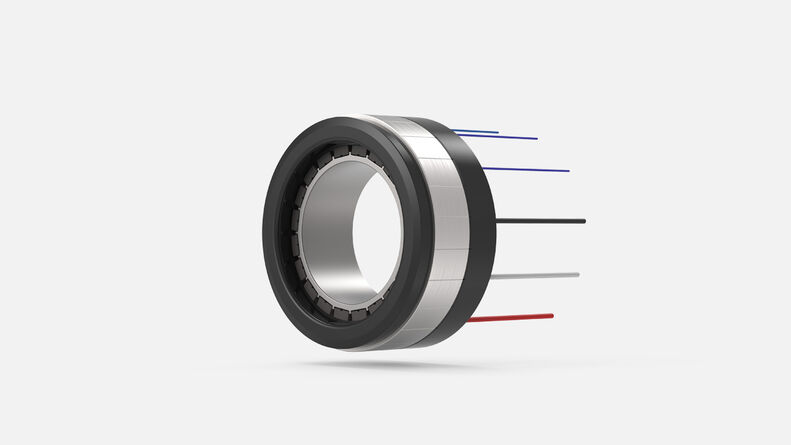

cyber® kit line small – frameless servo motors

high torque – highly integrated – flexible

The frameless servo motors of the cyber® kit line product family offer maximum torque and flexibility in a compact size. In additional, the frameless design with a large hollow shaft gives the maximum possible freedom of integration to develop unique solutions for specific applications.

The cyber® kit line assembly kit consisting of rotor and stator can be flexibly integrated into the machine thanks to the variety of variants.

Downloads

Webinar technical training:

How frameless servo motors are used.

In this webinar, you will learn about the possible applications of our frameless servo motors from a technical perspective. You will learn what to consider when selecting, sizing, installing and operating these motors.

Register now

Excellent solution for complex motion tasks

High torque

- Highest torque density thanks to maximum copper fill factor

- Torque motor with 20 poles

Integratability

- Frameless version

- Large hollow shaft

- Suitable for gluing

Flexibility

- 60 V and 600 V design

- Wide range of choices

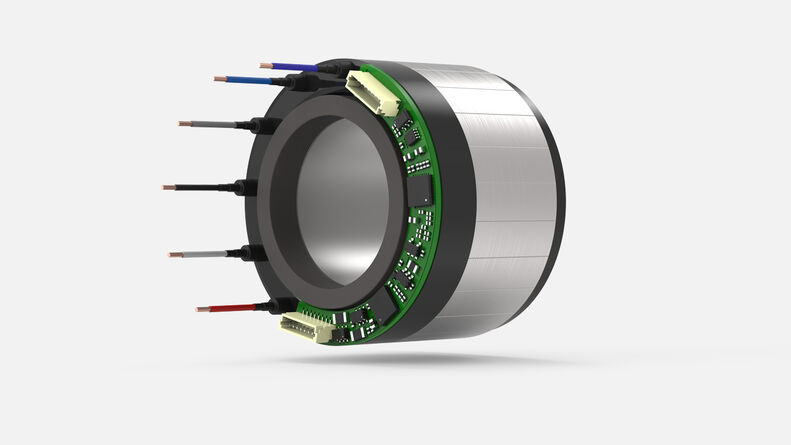

Connectivity

- Integrated PTC and PT1000 temperature sensor

- Optional Hall sensor

Dynamics

- Mass inertia optimized design

- 2 rotor variants for different applications

Reliability

- Complete potting for enormous robustness

- Maximum winding temperature of 140 °C for extended fields of applications

- Sizing safety

Product highlights

With a wide range of choices, the cyber® kit line offers maximum flexibility for the user. The torque-optimized motors offer a maximum of robustness due to their full potting and maximum integratability due to the frameless design with large hollow shaft. Combined with the integrated temperature sensors PTC and PT1000 as well as optional Hall sensor the motors open up many possibilities in terms of connectivity.

60 V and 600 V version

Large and small hollow shaft

Integrated PTC and PT1000 temperature sensor

Optional Hall sensor

Several lengths per size