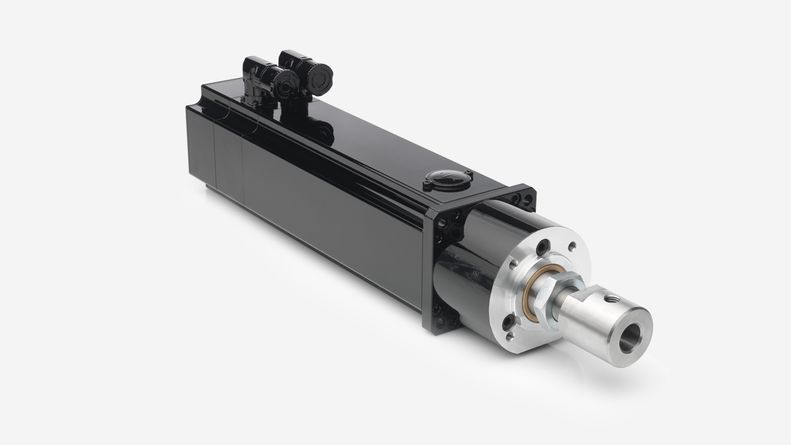

cyber® force actuator – linear actuators

reliable – compact – precise

cyber® force motors integrate a precision ball or planetary screw directly into a brushless servo motor for a uniquely compact package with flexible mounting options. The resulting linear servo actuator is reliable, durable, precise and delivers excellent dynamic performance.

With cyber® force actuators we are a worldwide partner in the Encompass program of Rockwell Automation.

Downloads

- Brochure / Flyer (3 MB)

- Operating manual (828 KB)

WITTENSTEIN - North America

1249 Humbracht Circle

Bartlett, IL 60103

1 630 540-5300