Screwdriving made simple

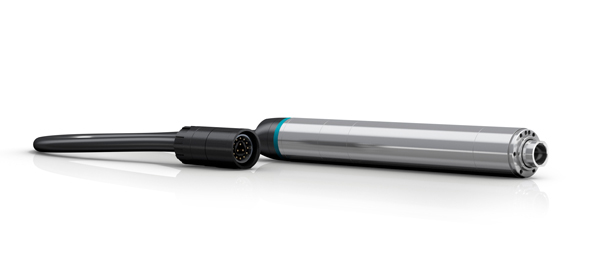

Assembly processes with tiny screws (e. g. M1 X 2mm), which are typically used for the assembly of mobile phones or hearing aids, represent a complex task for automated screwdriving systems due to the correct positioning of the screws and the low but precise torque requirements. STÖGER AUTOMATION, the screwdriving and fastening systems specialist, has come up with a groundbreaking handling and assembly solution featuring highly dynamic small servo motors from the cyber® dynamic line family and real-time capable servo amplifiers from WITTENSTEIN cyber motor’s cyber® simco® drive series.

A revolutionary development

With the small motors and drive amplifiers from WITTENSTEIN, STÖGER AUTOMATION was able to implement a highly innovative solution for the reliable provision, insertion and tightening of miniature screws without the need for additional sensors. A special MotionTask makes it possible to obtain and read out the torque precisely via the drive controller when tightening the screw. The compact external dimensions of the small servomotors suitable for industrial use, their low mass and intelligent drive amplifiers with a high switching frequency and an extraordinarily high current resolution are the decisive advantages of our drive solution for the company. In addition, there is the variable configuration of the interfaces to higher-level controllers, as the automatic srewdrivers can be used both as individual devices, e.g. in the version with an X/Y axis system and in large systems. WITTENSTEIN cyber motor has developed a linear actuator for the Z-axis to guide the screw during the screwdriving process, which convinces with its ideal functionality and high cost-effectiveness.