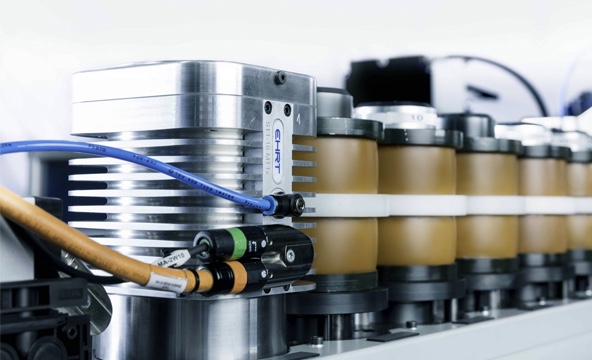

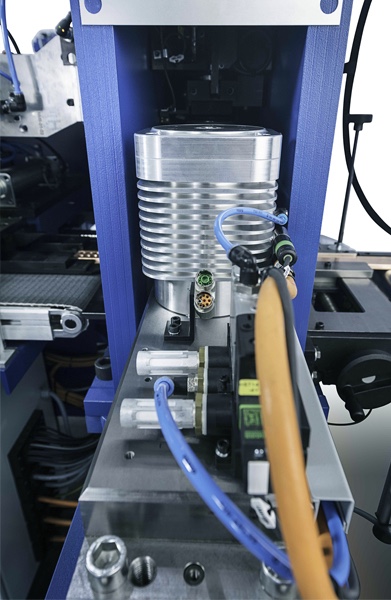

Optimally adapted: frameless motor for thread forming tools

To design a direct drive for thread forming tools in punching machines – this was the challenge at the center of a joint development project by EHRT Maschinenbau GmbH and WITTENSTEIN cyber motor. The key requirements were to increase the level of performance despite smaller mounting dimensions and achieve optimal integration into the existing machine architecture. The result – in less than six months the two partners came up with a dynamic and highly compact drive unit.

Impressive example of cooperative forward integration

The roles within this partnership were clearly charted out: EHRT developed the drawing parts while WITTENSTEIN designed a frameless motor to the customer’s specification with components from the cyber® kit motor basic toolkit. The two partners’ respective components are now being assembled into a drive unit and function-tested by qualified personnel in defined processes at WITTENSTEIN cyber motor. EHRT profits tremendously from WITTENSTEIN cyber motor’s know-how and process reliability. The engineering company is not forced to develop expertise in motor assembly but is free to concentrate on its core business. This project is an impressive example of how cooperative forward integration can work in practice.